HIC Testing Service

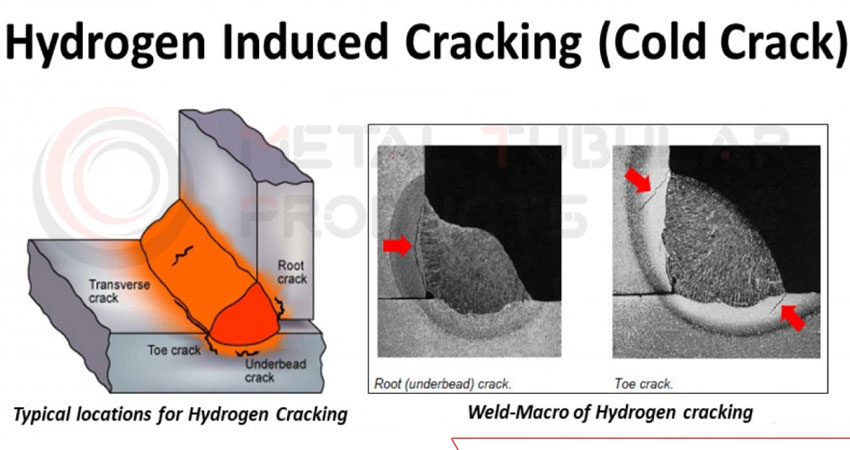

Hydrogen-Induced Cracking (HIC) is the stepwise internal cracks that connect adjacent hydrogen blisters on different planes in the metal, or to the metal surface. It is also known as stepwise cracking.HIC is especially prevalent in iron alloys because of the restricted slip capabilities in the predominantly body-centered cubic (BCC) structure. HIC is generally limited to steels having a hardness of 22 or greater on the Rockwell C scale.

Hydrogen-induced cracking results from atomic hydrogen being absorbed by solid metals. This can occur during elevated-temperature thermal treatments and in service during electroplating, contact with maintenance chemicals, wet H2S, corrosion reactions, cathodic protection, and operating in high-pressure hydrogen-containing environments.

Hydrogen-induced cracking (HIC) is a type of corrosion-related failure that occurs in certain metals when they are exposed to hydrogen gas in a corrosive environment. It is also known as hydrogen stress cracking, hydrogen embrittlement, or hydrogen-assisted cracking. HIC can lead to sudden and catastrophic failures in structures and components, especially in industries such as oil and gas, petrochemical, and chemical processing.

Applications Industry

| Pharmaceutical Equipment | Chemical Equipment |

| Sea Water Equipment | Heat Exchangers |

| Heat Exchangers | Gas Processing |

| Condensers | Specialty Chemicals |

| Pulp and Paper Industry | Pharmaceuticals |

Overview of how HIC testing works:

1) Hydrogen Absorption: Metals exposed to hydrogen can absorb hydrogen atoms into their crystal lattice, a process called hydrogen absorption or hydrogen uptake.

2) Hydrogen Migration: Hydrogen atoms can diffuse through the metal's crystal structure, eventually accumulating in regions of high stress, such as grain boundaries or other areas with microstructural defects.

3) Local Embrittlement: The presence of hydrogen weakens the metal's mechanical properties, making it more susceptible to cracking and fracture under stress, even if the stress is below the material's yield strength.

4) Corrosive Environment: HIC is often associated with a corrosive environment that provides the conditions necessary for hydrogen to penetrate the metal surface and migrate within it.

5) Residual Stress: Residual stresses from manufacturing processes or operational conditions can also contribute to the development of HIC.

6) HIC is particularly concerning because it can lead to catastrophic failures without significant plastic deformation or warning signs. It often occurs without any visible external corrosion or changes in appearance.

Preventing HIC involves several strategies:

1) Material Selection: Using materials that are resistant to hydrogen embrittlement and suitable for the intended environment can help mitigate the risk of HIC.2) Operating Conditions: Managing operating conditions such as temperature, pressure, and exposure to corrosive substances can reduce the likelihood of HIC.

3) Cathodic Protection: Employing cathodic protection systems can help reduce the likelihood of corrosion, which in turn can reduce the risk of hydrogen ingress.

4) Hydrogen Mitigation: Certain techniques, such as heat treatments, can help remove or reduce absorbed hydrogen from the metal's lattice, making it less susceptible to HIC.

5) Material Testing: Performing hydrogen embrittlement testing and assessment of susceptibility during material selection and quality control processes can help identify materials prone to HIC.

6) Inspection and Monitoring: Regular inspections and monitoring for signs of cracking or degradation are crucial for early detection of potential HIC-related issues.

7) Coating and Surface Protection: Applying protective coatings or barriers can help prevent hydrogen from penetrating the metal surface.

We supply Pipes, Tubes & Fittings Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.